Page 1 of 1

Oil level

Posted: Sun Dec 24, 2017 1:47 am

by 105gta.

Ill start with merry Xmas everyone.

I'm curious if anyone has done any serious checks of oil levels while running etc... today while making my windage tray/scraper I notice when I cut the dipstick hole that the factory full mark is dead in the level of the crankshaft counter weights. Obviously the rods and bolts will be even lower than he crank. I know the level will drop some when running but I'm curious as to how much? Everything I can find is based on pushrods v8's, which apparently drop the oil level 1.5-2.5 inches when running. But what about our v6's???

Has anyone looked into this or had any issues on the track?

Ben

Re: Oil level

Posted: Sun Apr 29, 2018 12:10 pm

by Melvivio

Check out motortrend engine masters.

https://www.motortrendondemand.com/det ... _iqs4grke/

Quick summary, it is better to run with oil free of the moving parts crank, towards the minimum level. Lower RPM there isn't all that much difference, but at the higher RPM, slush will create small air bubbles in the oil, not good. The pressure dropped due to that.

Re: Oil level

Posted: Mon May 07, 2018 2:59 pm

by MD

Good info but with respect to lowered pressures, I attribute that to a change in viscosity due to rising temperature in the oil.

Re: Oil level

Posted: Tue May 08, 2018 1:48 am

by Jim K

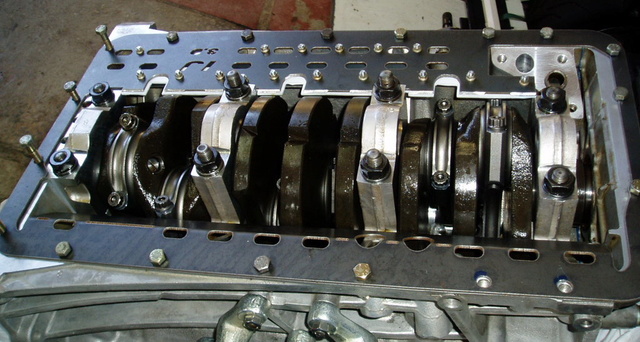

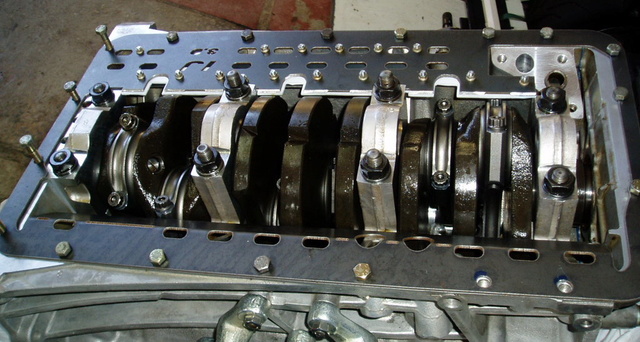

If you do trackdays, do your engine a big favor and install a crank scraper from Ishihara-Johnson. Additionally, you may opt for some kind of slosh-baffle. Here is what I have in my 3.2 engine. The scraper has the Teflon-edge option which you must very carefully cut yourself so that the rotating parts barely contact it -thereby removing substantial quantities of oil. Supposedly, this is worth ~2.5% more power...but so is a partial vacuum in the crankcase, easily attained by suitably connecting a small pipe at an angle to the exhaust pipe. I haven't done this last part, just experimented with it and almost emptied the oil sump wthin ~1000km!

Jim K.

Re: Oil level

Posted: Sat Jun 02, 2018 4:51 am

by Greg_Sef

No doubt that the crank scraper is worth some power - but you will need to CAREFULLY examine its fit and trim and file it to get it to sit correctly between the block and pan.

Right out of the box it interferes with some of the casting features and you will have a big leak in spite of how much RTV you spooge onto the interface. I lost a motor in an endurance race (9-1/2 hours) due to this leakage. This fitment problem is exasperated when you are fitting a rear wheel drive oil pan to an engine block from a 164 front wheel drive car.

So take your time and file - drill - grind etc. and make sure everything fits perfectly when using the crank scraper.

Greg

Re: Oil level

Posted: Sat Jun 02, 2018 9:54 am

by Jim K

Sure enough, it took me several days to get it to fit perfectly, a lot of filing and cutting the Teflon with Exact-O-knife, but in the end even I was happy with the rotating parts barely 'licking' the Teflon strip. And no oil leaks anywhere for more than a year now.

Jim K.