Page 1 of 1

Interesting Dry 24V Sump Project

Posted: Fri Feb 07, 2014 9:38 am

by 75evo

Re: Interesting Dry 24V Sump Project

Posted: Sat Feb 08, 2014 1:58 pm

by Giuliettaevo2

Very impressive work...

Re: Interesting Dry 24V Sump Project

Posted: Sun Feb 09, 2014 4:53 am

by Maurizio

Giuliettaevo2 wrote:Very impressive work...

like the saying: the wright tools is half the work, impressive machinery in that shed...

Re: Interesting Dry 24V Sump Project

Posted: Sun Feb 09, 2014 12:29 pm

by yetyGTA

Maurizio wrote:Giuliettaevo2 wrote:Very impressive work...

like the saying: the wright tools is half the work, impressive machinery in that shed...

Exactly. Amazing pieces. And I was so proud when I bought my Dremmel tool on Christmas.

Re: Interesting Dry 24V Sump Project

Posted: Mon Feb 10, 2014 8:36 am

by 75evo

I want to buy a Grizzly G0704 mini mill. Then convert to CNC. Labor is too damn expensive here. Just imagine if a machinist was 5 hours to get brackets done. That's $550 for labor alone. HJ&^*&GJ!!!!!

For really specialized and super accurate components, I won't machine it myself. But for the few parts I need which need to be fairly accurate like 1/100", why should I pay $200 (usually most shops want a minimum of 2 hours).

Cost is $1200, tooling another $500+, CNC conversion another $1000. But in the end it will be worth it.

Re: Interesting Dry 24V Sump Project

Posted: Mon Feb 10, 2014 10:57 am

by kevin

Z , I think that's a great idea and when you have perfected that art I will be sending you a whole lot of parts to copy

Re: Interesting Dry 24V Sump Project

Posted: Tue Feb 11, 2014 2:13 am

by yetyGTA

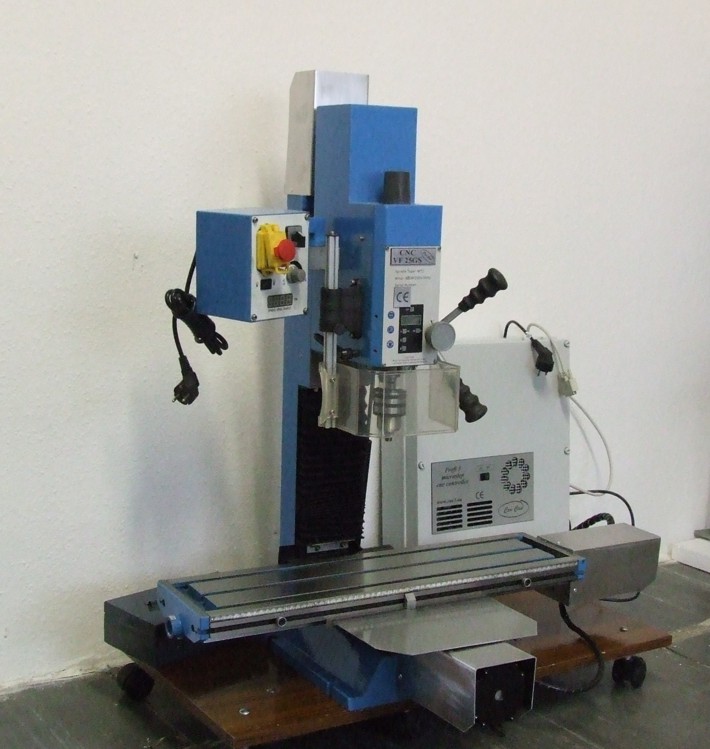

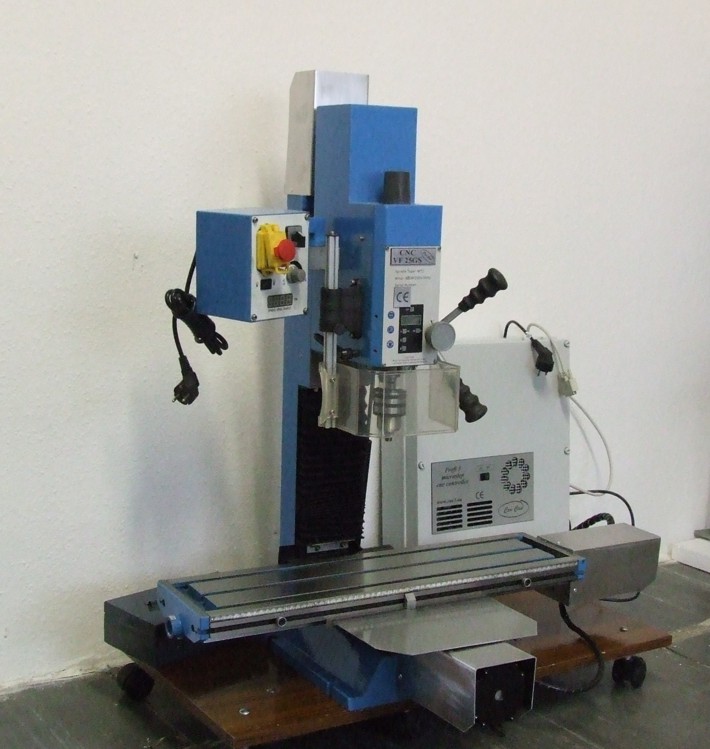

Good idea Evo. Found somthing similar already as CNC for 2.600 EUR. Just the operating diameter seems quite small 400x100x250. Just wondering if the table can be enlarged afterwards.

http://www.ebay.de/itm/3D-CNC-Frasmasch ... 27de68518b

Re: Interesting Dry 24V Sump Project

Posted: Tue Feb 11, 2014 9:34 am

by 75evo

You just need a bigger machine. I think going slightly bigger won't cost you much more. You will usually get a more powerful motor too. But I'm just thinking of basic machining. Small brackets that needs some level of precision and not simply using an angle grinder and a hand drill.

Those days of grinders and drills have passed....sort of

This reminds me of a Benny Hill joke:

Home Made Pie:

-------------------

Pies that Mom made $5

Pies that Mom tried to make but couldn't $7

Re: Interesting Dry 24V Sump Project

Posted: Sat Feb 15, 2014 11:20 pm

by MR2 Zig

You can have parts overhang the end/edge of the table just as long as you can reach with the cutter. Me, being a machinist, think you'd be better off buying a cnc vertical mill, used, but of a more professional size and construction. Please remember that there is a reason that it takes 4 years to turn out as a journeyman....there is more to learn about machining than you might think.

Re: Interesting Dry 24V Sump Project

Posted: Sat Feb 15, 2014 11:26 pm

by MR2 Zig

That kind of machine will work fine on aluminum, plastic or wood. Steel is a different thing. I can't tell if the drill chuck is the only chuck or not, but they don't take side loads of milling well (they can and will let the cutter move up or down in the chuck). You'd go bonkers at how slow it would be to cut an exhaust flange cleanly.

Re: Interesting Dry 24V Sump Project

Posted: Sun Feb 16, 2014 12:45 am

by Mats

MR2 Zig wrote:That kind of machine will work fine on aluminum, plastic or wood. Steel is a different thing. I can't tell if the drill chuck is the only chuck or not, but they don't take side loads of milling well (they can and will let the cutter move up or down in the chuck). You'd go bonkers at how slow it would be to cut an exhaust flange cleanly.

+1

A guy in my garage has exactly the fancy drill press you show in yor post but with a milling chuck. On steel it's useless, it lex so much the tool just bounce off the surface and break the cutting edges...

Re: Interesting Dry 24V Sump Project

Posted: Sun Feb 16, 2014 3:46 am

by Maurizio

+2

Machines you need to some real stuff aren't cheap any more...... Then the next is the cutters, clamp tooling, measuring tools etc. Plus you have to have enough spare time, to actually do this stuff.

Such milling machines are only cost effective if you do it for a living and have good customer base!

Or you see it as a hobby then cost effectiveness is not a factor any-more, your total budget is...

Put your time in designing: function / price effective parts and provide a specialist with good working drawings. So that he doesn't have to invent the wheel for you.

Hint: Make it cheaper by making a small series and sell them to other enthusiasts...

Re: Interesting Dry 24V Sump Project

Posted: Sun Feb 16, 2014 10:14 am

by Jim K

Go find and buy a good used Bridgeport milling machine and be done with it! You can get real good ones for up to $2.5k. For most automotive stuff you don't need cnc. If you need to be extra precise, you can also add numerical control readout.

If I had one here, I could make up the purchase cost by making brake caliper adaptors for guys going big brake, as machine shops charge ~100-120€ for a set.

Jim K.

Re: Interesting Dry 24V Sump Project

Posted: Sun Feb 16, 2014 12:35 pm

by 75evo

Real machines need real work space, not a make do garage space. I agree a good used Bridgeport or Rong-fu is what I should get, but those things are unwieldily beasts when it comes to moving them around! When I get a dedicated shop, that's what I will get. The plan is to do mostly aluminum. The G0704 can do steel, but it has to be done extremely slowly because it doesn't have the mass or rigidity. For thick steel I'd have to send it out to my machinist.

like the saying: the wright tools is half the work, impressive machinery in that shed...