ELECTROPLATING

Wanting to ensure a real nut and bolt restoration, I had invested in a sandblasting unit from Adendorff (yes the reason they are doing so well is because of me !!! - have spent a pretty fortune there over the last while!!).

Maybe for another post but the system is not as simple to use as you may think. MANY things need to work together to have a sandblasting experience that is both efficient and effective. The most important thing is LOTS of air volume and pressure. I have a 150l W configuration compressor and quite frankly believe you should have nothing less than 200-250l and even better on 3 phase.

I have been using aluminium oxide as the substrate for the tougher cleaning and very small glass beads for the more sensitive items like aluminium.

With items nicely cleaned up, it was time to figure out how to do plating myself. This would be ZINC plating with a Yellow passivate to create not only a robust coating but also that visually appealing gold iridescent colour.

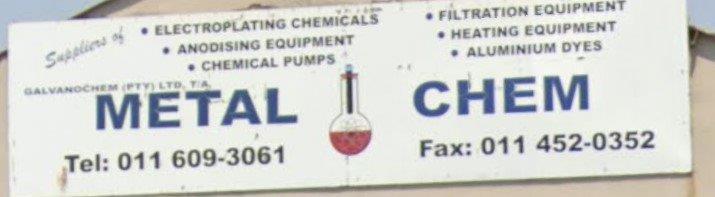

I initially made us of Tshwane Plating Suppliers to get the chemicals and zinc anodes, but more recently go to Metalchem in Edenvale.

So here is an overview of the process. IT IS TIME CONSUMING but also very satisfying!

- Metalchem to get plating supplies from in Edenvale

- 00.jpg (21.78 KiB) Viewed 124 times

- Example of item to be restored

- 01.jpg (135.8 KiB) Viewed 124 times

- Rear suspension bolt stripped down

- 02.jpg (163.76 KiB) Viewed 124 times

- Sandblasted and really cleaned up

- 03.jpg (159.65 KiB) Viewed 124 times

- Ready for chemical cleaning

- 04.jpg (164.14 KiB) Viewed 124 times