I've been working on my 3.2 project on and off for some time now, as the 3liter 24v will go into a friend's 75 when the new lump is ready. Since its a separate project I started this thread. Yesterday I got done with all block machining work, crank balancing, clearance setting, align-boring. I stayed at the machine shop all day to see everything through and help the guys out with whatever. I was especially interested in finishing the balancing job with the sensitivity knob set at 'max' -not usually done...

The block comes from a 164 which broke a rod, bent 8 valves... No head damage though. Lots of preliminary work was done at home like rod/piston balancing, cleaning, crank tapping, valve spring matching etc.

What is going into it:

3.2 crank (

CPS pistons

Maxspeeding rods

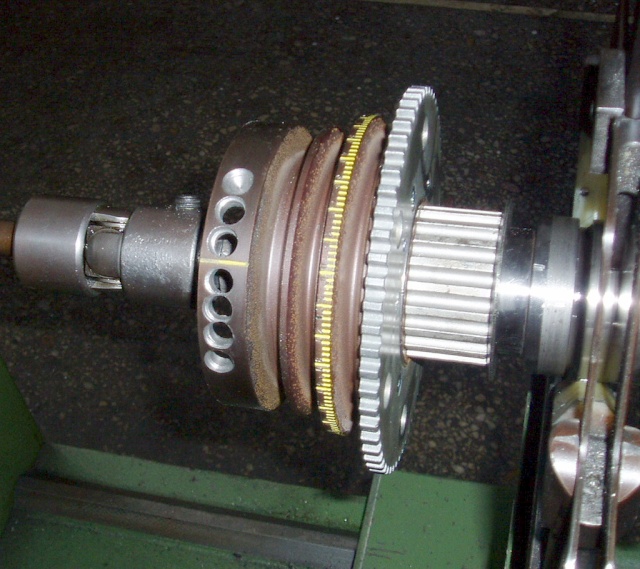

Lightened flywheel

75 Motronic pulley

Threaded crank oil plugs

IH crank scraper

Flowed/ported heads 11.5:1cr

Ferrea std size valves

JK 10.3 cams

JK 24v headers

Optimised oil pump

Long intake w/large plenum/short 75 intake+plenum (choice later)

Emerald K6 ecu/164Q4 (both will be used/mapped)

Details will be posted as we go. Here are a few pics.

Jim K.