Max CR is a function of cam duration and available fuel. We can leave fuel out since we have very good 'premium unleaded' pump fuel -called 100octane gas here- so we are left with the cams. Here is where the simulator helps. We are looking for as good a

dynamic CR as we can get and from that we can find our geometric CR, or we can work backwards by searching which geometric CR will give us a high DCR, but no more than ~9.5:1. This helps:

http://www.wallaceracing.com/dynamic-cr.php

I would think 11.5-11.7:1 to be a practical CR for a trackday car.

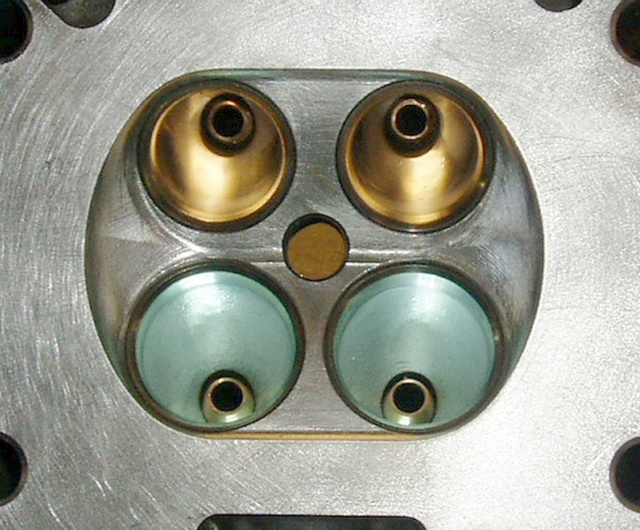

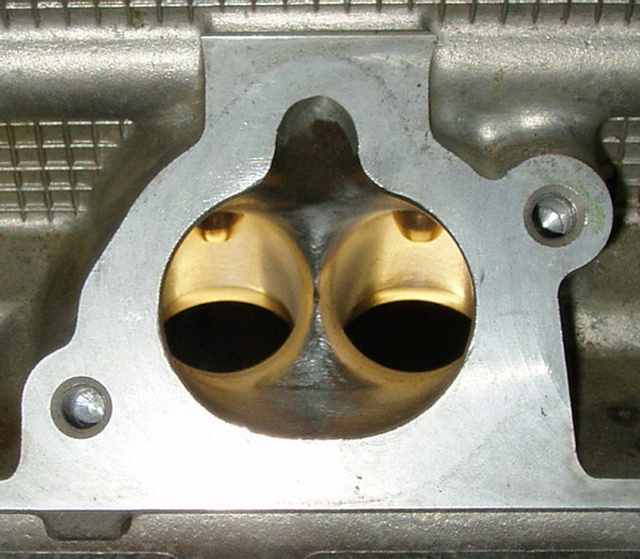

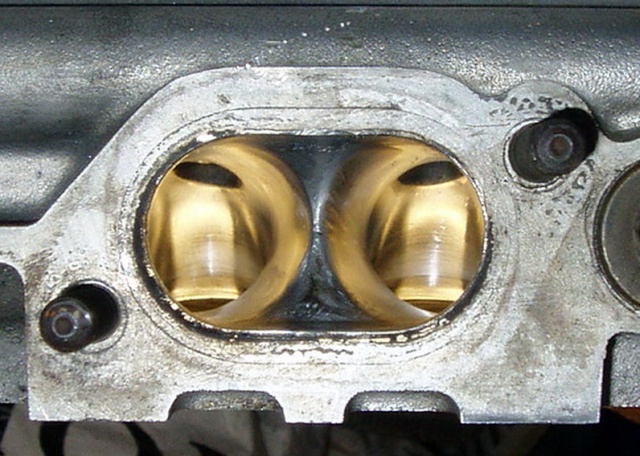

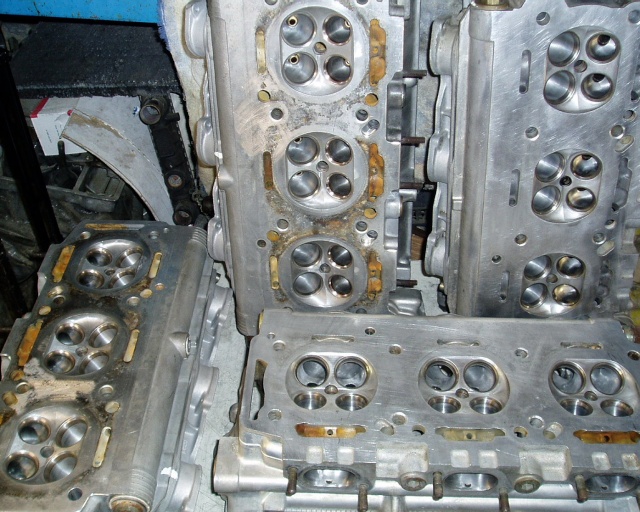

Today I installed the guides in the second set of heads. I had to hammer a lot with the exhaust guides as they were ~0.01mm thicker than the last set (different manufacturer). As a result, they tightened when in place so tomorrow I'm taking the heads to the machine shop to use their 7mm reamer. The seats will also be cut at the same time.

Measuring CR and how much to mill off the heads: After the seats are cut and I lap the valves, I will install valves in cylinder #2 or #5. Old head gaskets will be used and the heads torqued down. With the respective piston at TDC, the engine stand will be tilted so that the gasket is horizontal...

This you will have to see and laugh at, its a major undertaking given the type of stand I have! I have high compression pistons, so what I end up milling will probably be of no help to anyone. With my 10.3 cams, 112* lobe centers and 11.6:1 cr, dcr comes to 9.5:1 which is ok.

More news soon including valve/piston clearance measurement...

Following that, both head versions will visit the flowbench...moment of truth!

Jim K.